Drilling and Workover Services

Petroleum Barrel and its workforce have pride in our company and equipment, and in delivering world class quality in Rig operations, We strive for continuous improvement, one of our founding pillars.

For every operation we utilise the following actions to provide the ultimate service quality

- Collaboration with the Client, to ensure safe and successful operation.

- Effective coordinatization with the operation and service companies.

- Monitor, measure and continuously improve.

- Top-performing drilling rig built for deep, long-reach horizontal wells, and innovations continue to improve our results.

- World class well control manual to support our operations.

- Professional people with the experience, knowledge and competence to operate and maintain our rigs.

- Selection of the best-fit service companies to best contribute to the operation.

- Arrange all material tangibles required to drill and complete the well in a timely and efficient manner.

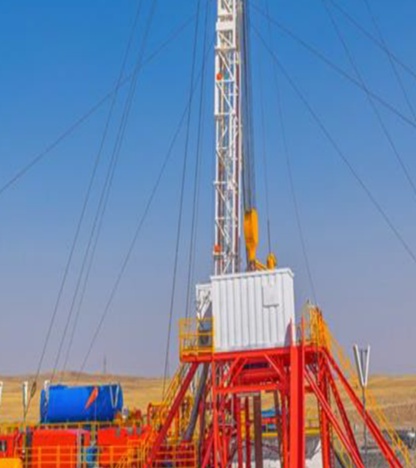

Rig Details

Petroleum Barrel Owns Rig PB-941, a 2000 HP unit reconstructed in partnership with Exxon Mobil and certified by Moduspec to meet the highest Safety and Regulatory Compliance standards. CAT IV compliant and completed January 2022.

- Mast: Soilmec Branham Cantilever, Static Hook load 1,000,000 lbs

- Sub-structure: Soilmec Branham/Slingshot self-elevating (9.14m height)

- Draw works: Oilwell E2000 (2,000HP/1,490kW) Input: GE 753 x 2 (1,000HP/750kW)

- Top Drive: Varco TDS 11S, 100% rebuilt and certified.

- Rotary table: Oilwell A37.5 (37.5 inch opening)

- Pipe handling: Varco ST80 Iron roughneck

- Mud Pumps: 3 x Emsco FB 1600 (power rating 1600HP)

- Mud System:

- Active system 317m3 (1994 bbl)

- Reserve tank 200m3 (1258 bbl)

- Water tank 95m3 (598 bbl)

Turnkey operations – track history

Rig 941 drilled 4 infill horizontal wells in record time, the fastest being from spud to rig release of 17 days. The wells were drilled within the terms of the contract and under budget with less than 3% NPT overall. This was an outstanding performance considering the rig had been stacked for 7 years prior to the drilling campaign. Rig 941 then moved onto a Jurassic exploration well, and drilled to 3050m in 101 days, meeting all the objectives. This was 80 days quicker than the nearest offset well.

Petroleum Barrel were providing the DST and surface well testing equipment including the ESP package for well testing of heavy oil from the formation. This was a complex well test and Petroleum Barrel rose to the challenge providing all the equipment and experienced personnel to make the testing successful and providing all the data required.

Throughout the Client / Petroleum Barrel relationship, Petroleum Barrel always fostered a “One Team” approach and accommodated the client’s operations requests and rapid procurement due to changing well designs, with efficiency and professionalism.

Workover Rig

Petroleum Barrel also has access to workover rigs including the rig detailed below

Rig ZJ-40 / CZ (E), - Fit for drilling and for workovers

| Mast: | Telescopic double, Static Hook Load: 500,000 Ibs. |

| Sub Structure: | (6m height) |

| Drawworks: | 2 x Cat C18 (1,000 hp / 735 kW) |

| Top Drive: | Varco TDS 115, 100% rebuild and certified |

| Rotary Table: | Oilwell A37.5, 37 ‡" Opening |

| Rotary Table: | ZP 275, 27 ½" Opening |

| Mud pumps: | 2 X N3NB, Power Rating: 1300 HP |

| Mud System: | Active System 85m3 (535 bbl.) Reserve Tank 70m3 (440 bbl.) Water Tank 64m3 (402 bbl.) |